QFN package

Home > IC Packaging >

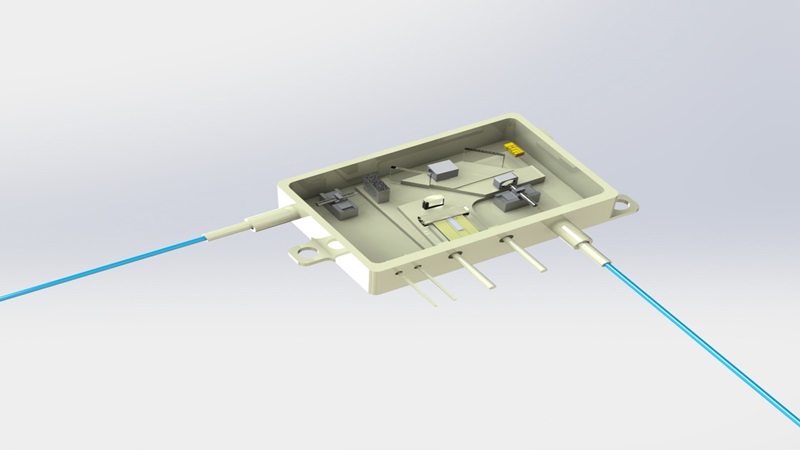

Following validation of chip designs through our Fast Turn prototype service, ALTER offers customers ramp-up and production volume assembly in QFN overmoulded packages.

We offer low-cost plastic encapsulated QFN package for batch sizes from 100pcs to several 1000s, with a total capacity of millions per year.

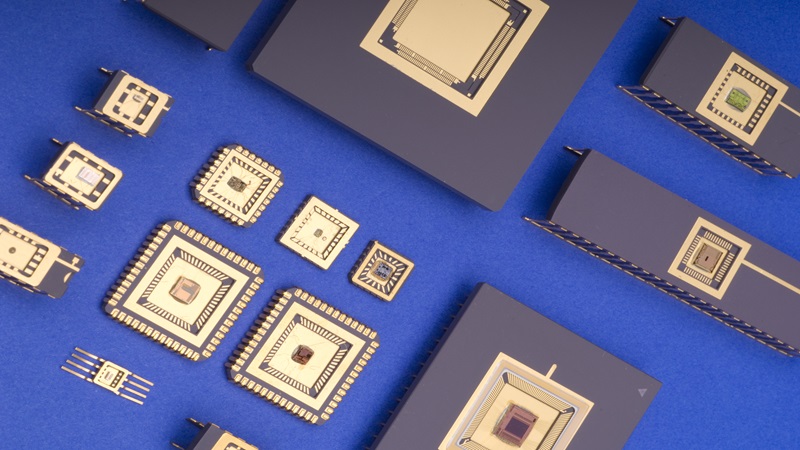

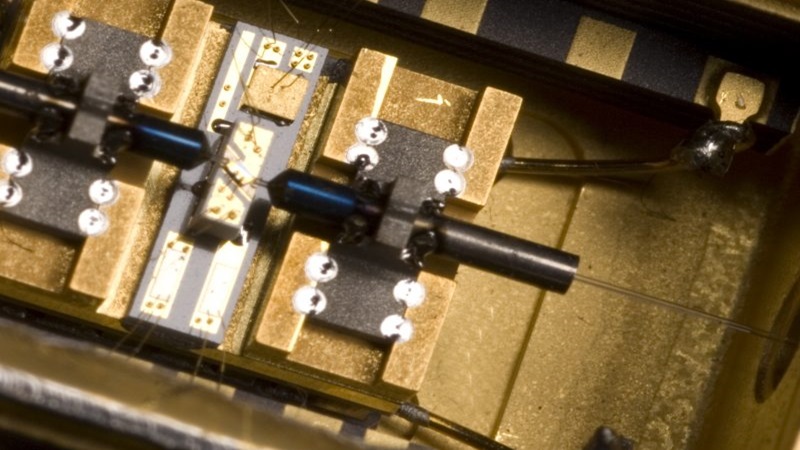

QFN packages are based around an etched copper alloy lead frame array panel with multiple devices per array. Customers die are attached to the leadframe typically with silver loaded epoxy, and wire bonded with automatic systems enabling high throughput and consistency. The leadframe panels are thenover molded with epoxy mold compound, laser marked and diced into single packages. A range of open-tool lead frames with QFN body sizes from 3x3mm to 9x9mm are available in stock to accommodate most die sizes and pin counts.

Customization of package size and pin-count can be achieved by designing and tooling new lead-frame etching tools at very low NREs. The use of common block molding tools and saw singulation make this an incredibly flexible platform, many package configurations can be accommodated with the same equipment and tooling.

ALTER’s automated die and wire bonding, combined with panel lead frame molding means we have a capacity for several million of QFN packages per year.

The plastic QFN package achieves >90% cost reduction in production compared to the equivalent sized ceramic or open-cavity plastic package. They are packed in JEDEC standard trays which are suited for high-throughput automated pick & place testing, or tape & reel available on request.