Hermetic packaging

Home > IC Packaging >

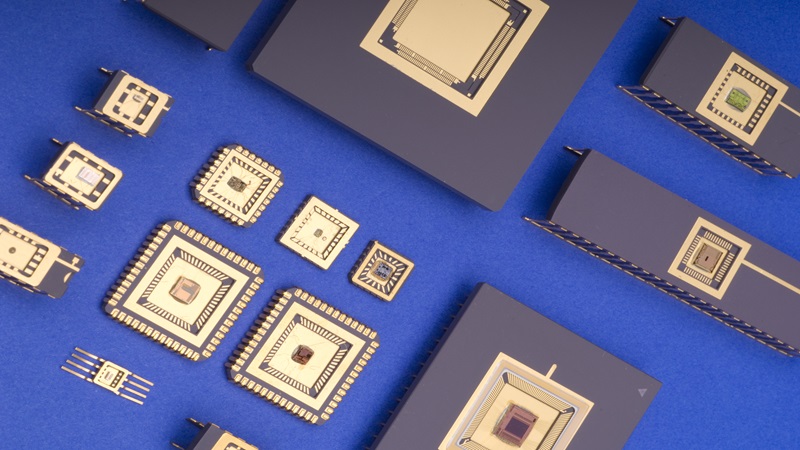

We offer hermetic packaging of die into robust ceramic and metal packages for high-reliability and harsh environment applications such as space, aerospace and defence.

We provide a range of assembly services for hermetic packaging includes:

- Wafer Saw

- Die bonding (eutectic and epoxy attach)

- Au Ball, Au/Al Wedge and Ribbon wire bonding

- Wire pull/Die Shear

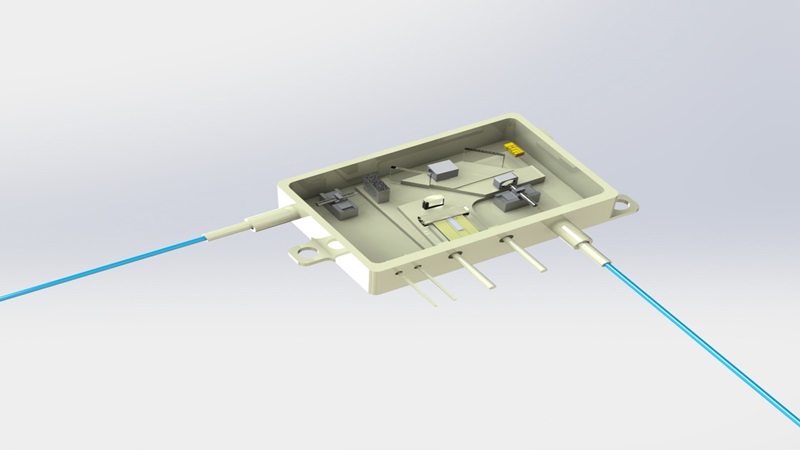

- Fiber alignment and attach

- Internal visual inspection

- Hermetic sealing

- X-ray imaging

ALTER UK provides a hermetic assembly of various metal and ceramic package configurations, including CQFP, CPGA, TO-can packages and Butterfly packages for harsh environment applications for which quality and reliability are a must, along with an efficient supply chain. Recent investments have added ISO class 7 compliant clean rooms to our facility to enable the assembly of flight model components for space applications.

Aluminium or gold wedge bonding is available using our Delvotec hybrid bonder. Also, gold ball bonding can be offered with hi-reliability 2N (99.00% Au) wire. MIL-STD 883 test methods are applied for wire pull, die shear testing and pre-cap internal visual inspection. Assembly flows up to ESCC9000 compliance can also be offered on request.

Prior to sealing, packages are put through a vacuum bake-out process to remove moisture and other residues from the component surfaces. Using an N2-filled glovebox, parallel resistance welding can seal square or rectangular packages. Projection welding is used for TO-can devices.

A vacuum reflow furnace is also available for solder sealing of packages with AuSn preforms. This method can be used to seal the package with N2 backfill, vacuum or a variety of inert gas atmospheres, including N2, Ar, and O2, depending on the customer’s exact requirements.

Fine and Gross leak tests are carried out to MIL-STD-883. ALTER has achieved leak rates of <5E-9 for fiber-coupled butterfly packages. This can potentially reduce the length of lifetime tests in certain applications.

Real-time microfocus x-ray is used to inspect the epoxy or solder coverage of the die attach and the quality of welded or solder joints in the package assembly.

ALTER’s expertise in hermetic packaging

ALTER’s expertise and capability in encapsulation and hermetic sealing will reduce risk and reduce time to market as well as provide a cost-effective manufacturing option.

ALTER also offers full design and assembly of custom products, including package and lid design and procurement. Finite element analysis can be included to select the correct materials for the customer’s thermal requirements, and mechanical stress modelling can be used to evaluate the package and de-risk the design from failures at later stages of the qualification.

ALTER’s quality management system is certified to EN9100:2018, which incorporates ISO9001:2015, we are also JOSCAR registered for fast supplier onboarding for the defense community.

Download Datasheets for advanced packaging solutions

Explore our expertise through ALTER's Packaging and Assembly datasheets. Click now to explore cutting-edge solutions, from fast IC prototype packaging to advanced hermetic sealing. Discover our capabilities in ASIC packaging, MEMS, laser diode modules, and more.

Access to Datasheets 25 KB | PDF