ALTER offers complete life-cycle support to ASIC design companies, including fabless device manufacturers, design houses and start-ups.

- Fast IC prototype packaging

- Overmoulded QFN ramp-up

- Volume production

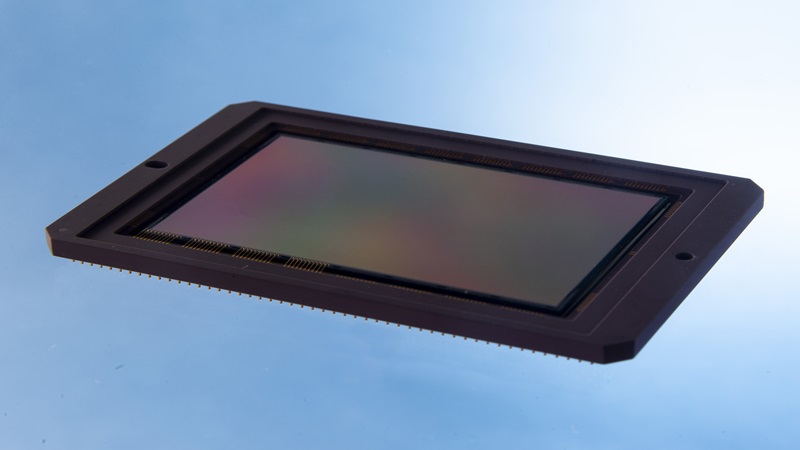

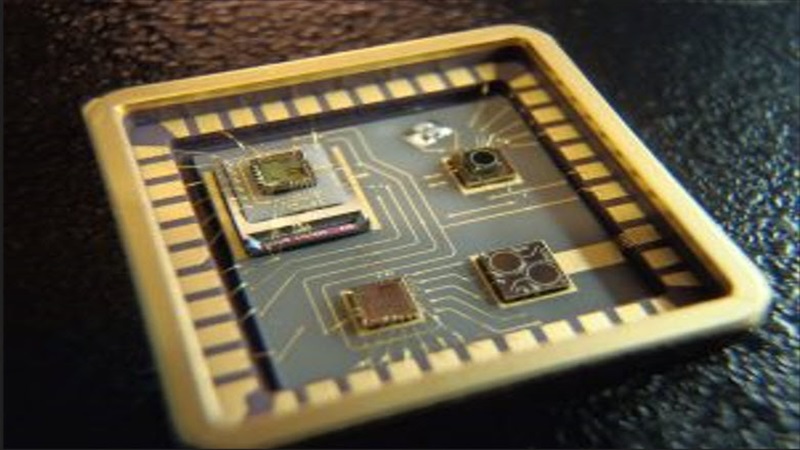

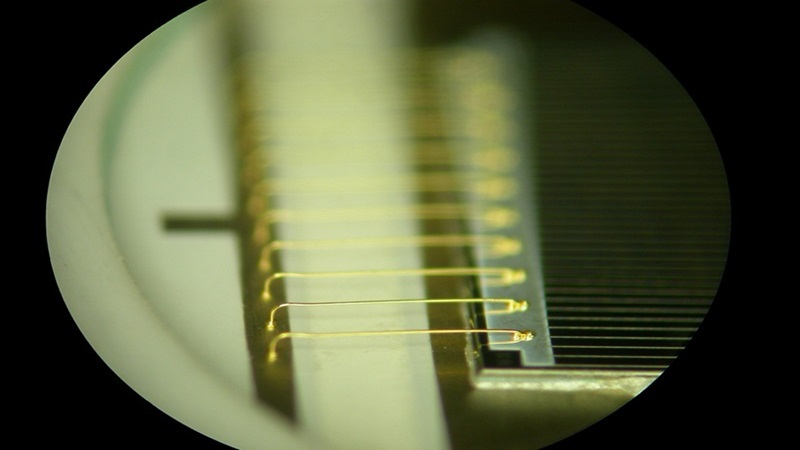

Our Fast Turn Prototype assembly supports the validation of new ASIC designs with rapid turnaround packaging using standard open-tooled packages. Typically customers receive 50 dice in a waffle pack from a multi-project wafer which can be assembled within 5 days and returned to the customer for testing and validation.

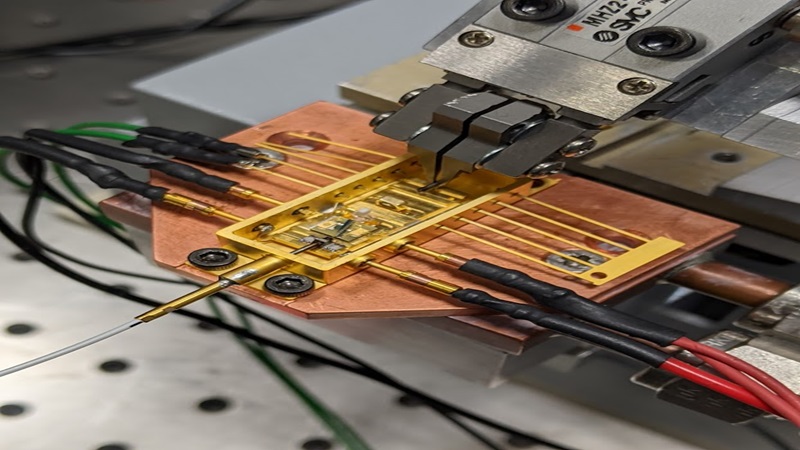

Pre-production and volume ramp-up are supported by our volume over-moulded QFN packaging, offering European customers a local production packaging solution. Initial batches from 100 PCs can be supported, as well as ramping through the thousands with capacity for several million QFNs per year. An automated assembly approach offers low cost and fast turnaround without the need to ship wafers overseas which increases lead times.

ALTER offers a range of standard open-tooled leadframes based on industry standard package sizes and pin-counts which cover a large range of ASIC designs. Beyond that, lead frames can be customized at a low cost by the use of dedicated leadframe etching masks. Standard tooling is used to mould the QFNs in an array panel format, therefore a high level of customization can be achieved with new lead frames and equipment programming for die bond, wire bond and singulation.

QFN packages are packed in JEDEC trays as standard, these trays are compatible with high-throughput pick and place test handlers, and tape and reel packing can also be provided on request.

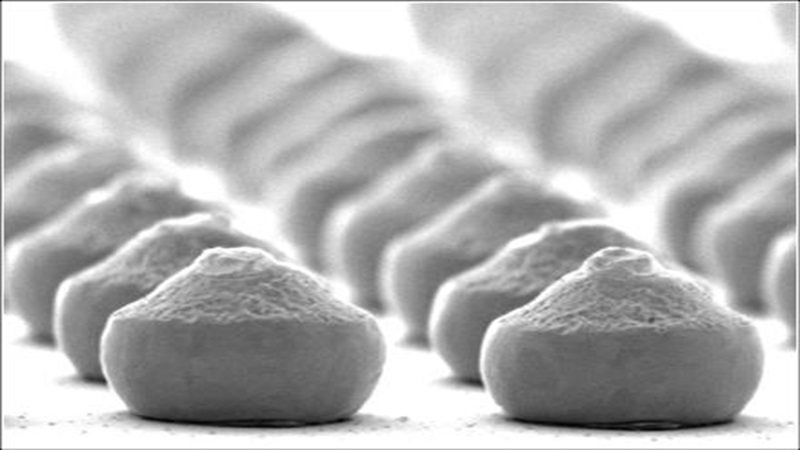

ALTER can accept customer’s wafers directly from the wafer foundry, and provide a complete back-end service including electronic wafer sort/probing, thinning and dicing, packaging and final test.