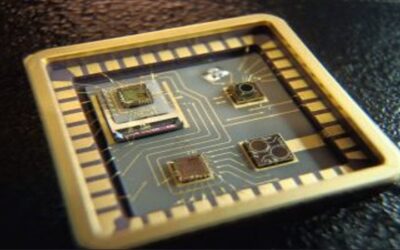

ALTER UK offers customers support in both prototype/process development for RF and Module packaging as well as volume manufacturing capability. By prototyping on the volume manufacturing tool-set ALTER UK can offer a risk-free transition to manufacturing with a fully optimized and high yield process.

As RF modules run at very high frequencies the effects of capacitance and stray inductance become even more important. The RF module must be designed and assembled with an understanding of these effects.

These processes can be coupled with any of ALTER’s Packaging platforms such as plastic overmoulded QFN and Photonics packaging to provide a complete solution for your RF device.

ALTER UK’s expertise and capability in RF Module Packaging will reduce risk and reduce time to market for your laser RF module packaging requirements as well as providing a cost-effective manufacturing option.

ALTER’s RF and mm Wave test laboratory in Seville can provide testing and qualification of RF devices up to 55GHz.

ALTER UK’s RF Module packaging expertise

- Process Highlights

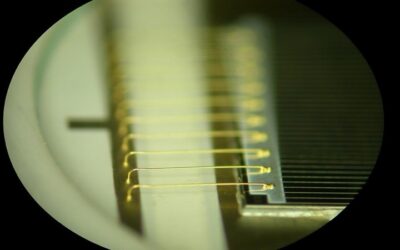

- Controlled wire bonding on automated equipment for optimal wire bond loop profile

- Wire bond length control less than 75um

- Gold ball

- Wedge-Wedge

- Ribbon bonding (25umx50um, 25umx75um)

- Non-contact handling process for MMIC die

- Accurate placement of die to transmission lines

- Materials

- Substrates: Duroid, FR4, Ceramics

- Conductive or Eutectic Die attach

- Products: RF transmitter/receiver modules/Optical RF Modules.

ALTER UK, the standard platform provides several key benefits:

- Avoids Design and Development NRE charges.

- Utilises Telcordia/Space compliant processes and materials.

- Enables faster time to market by utilising off-the-shelf components and avoiding key technical pitfalls.

- Provides competitive unit prices based on automated assembly processes and utilising economies of scales for purchasing materials.

ALTER UK, the standard platform has the following features:

- Wide range of packages including 14-pin butterfly packages and TO-cans.

- PM, SM, MM, Polycrystalline, High-temperature fibres and FVA’s including lensed options.

- Laser weld or epoxy attach of fiber assembly

- High-quality AR coating with a variety of lens designs to maximise coupling efficiency

- Solutions for a wide range of devices and wavelengths including DFB, DBR lasers, SOA’s, SLD’s VCSEL’s, Photodiodes and Quantum Cascade lasers

- Isolators and Free-Space optics

- Thermistor, TEC and Monitor Photodiode

Related Blog

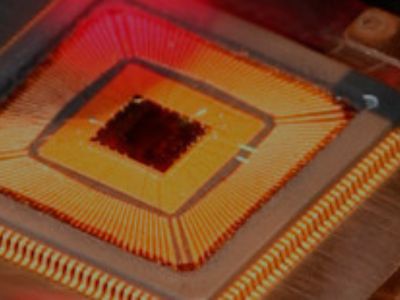

ASIC Packaging

ASIC packaging excellence from ALTER: Fast prototype, QFN ramp-up, and volume production. Rapid validation for efficient ASIC design testing.

MEMS Packaging

ALTER excels in MEMS packaging, precision assembly of inertial sensors, accelerometers, microfluidic, and optical MEMS devices.

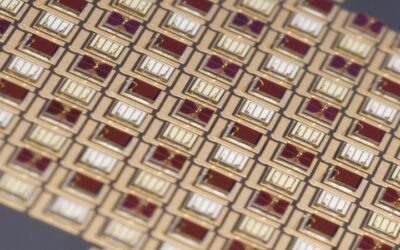

LED Chip-On-Board

LED Chip-on-Board benefits and advantages: cost-effectiveness, custom arrays, enhanced efficiency, and reduced ownership costs.